“Change is the law of life. And those who look only to the

past or present are certain to miss the future.”

-John F. Kennedy

Experienced boat owners are familiar with the haul-out ritual (and the anxiety associated with it). Most of us are too nervous watching our precious babies being hoisted up out of the water onto the slings to pause and appreciate the lift itself, but there’s a lot going on worthy of our interest. Industrial-sized boat lifts are far more than simply metal crossbeams with cables, especially these days when innovation increasingly reigns over tradition both on and off the water. New players on the industrial boat lift scene, notably in Italy, are starting to break out designs that resemble remote-controlled robots more than maritime forklifts. Even features like the cab, the cage in which the operator manually controls the lift, are being phased out. The imagination goes a bit wild at this juncture. Perhaps boat lifts will be taking verbal commands in the near future? Hal from 2001: A Space Odyssey could become a cautionary tale.

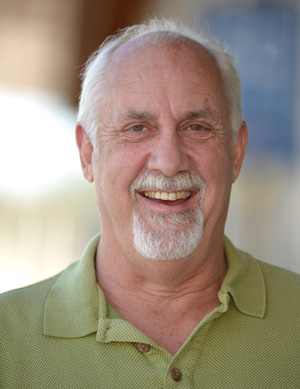

To learn more about boat lifts, we turn to Phil Riise, owner of Seaview Boatyard, Inc., for his insight into the topic. Riise owns and manages three boatyards in Washington and is well acquainted with the industrial boat lift market, having just purchased a brand new, state-of-the-art Italian boat lift from the company Boat Lift. The new 80-ton machine is expected to be installed come October at the Seaview Boatyard in Shilshole Bay Marina.

To learn more about boat lifts, we turn to Phil Riise, owner of Seaview Boatyard, Inc., for his insight into the topic. Riise owns and manages three boatyards in Washington and is well acquainted with the industrial boat lift market, having just purchased a brand new, state-of-the-art Italian boat lift from the company Boat Lift. The new 80-ton machine is expected to be installed come October at the Seaview Boatyard in Shilshole Bay Marina.

Q: Firstly, I’ll state the obvious and say that I know next to nothing about the boat lift world and I’m looking forward to learning a thing or two. Do you have any tips for boaters who are planning to utilize a yard’s lift?

The first thing that a boat owner really needs to be aware of is, no matter where they go, is to know the bottom of your boat. Critically, know where the shaft exits the hull. Go online and make sure you have an underbody drawing of your boat and make sure the operator knows where to set the slings. If you don’t have that, it’s at your fingertips so you’ve got no excuse. At our yard we have a boat catalogue so we know where to set the sling. It’s imperative the boat owner makes it his or her responsibility as well. The operator needs to know way before the boat is in the slings.

Number two, it’s a good idea for the boat owner to take an assessment of the lift. Are the slings dirty or worn? Is the lift clean and orderly, or is there oil dripping everywhere? Everyone should understand where to haul the boat and are things in good shape. Presentation is a big deal in this business. If things look pretty rough, you should consider hauling elsewhere. We at the Seaview yards have a strict maintenance regimen.

Q: Are there many different kinds of industrial boat lifts?

You bet. There are several lift manufacturers that build machines around the world. We’ve got two or three main ones in the United States, with the clearly dominant one being Marine Travelift of Sturgeon Bay, Wisconsin. There used to be more industrial boat lift makers in the States, but it’s principally down to three. For our lifts, starting in 1980 when we bought our first, we’ve bought 13 Marine Travelifts over the tenure of our business.

We’ve mostly been very satisfied and they are the local standard. Interestingly enough, though, Italian boat lift manufacturers seem to be on the rise, and they have two or three players as well. I decided to expand my horizons a bit when I knew we needed a new lift for the first time, and have been very impressed with some of the Italian companies.

Q: So Travelift is a brand, not a type? One always hears Travelift as if it is a type of machinery, but is it more like saying Ziploc instead of plastic bag?

Yes, Marine Travelift is a brand and it’s been in business for a long time, I want to say since the 1950s. I was good friends with original owners of Travelift and bought all my lifts from them except this last one.

Since I’ve owned and operated 13 Travelifts, most of the time I’ve considered them the Cadillac. They still build a good lift to this day, and are still widely considered the industry leader. But like everything, you have to continue to innovate and be competitive in the marketplace, and there are other ones that are nipping at their heels now.

Q: What kinds of innovations helped lead Marine Travelift to the top?

In the case of Marine Travelift, they had superior maneuverability and features that separated them from the competition. Ninety-degree steering was new back then, so the two rear tires could stay stationary during a turn and the lift could move in place. Maneuverability with the Marine Travelift was key, and it made them superior to everyone else out there at that time and for the foreseeable future, up until recently.

Although he says his family was too poor to own nice Tonka truck toys, he now proudly says, “I get to play with life-size Tonka toys.” His son, Tiel Riise, works with Phil at Seaview as Vice President of operations. Of Tiel, “He couldn’t make a father more proud,” says Phil.

Also, the maneuverability of the adjustment of the slings was new. Our first machine had one sling that was adjustable with the other fixed, an AMO model. That used to be new, but now there are two different styles. With the older AMO models, one sling hoist is fixed so that it will not move while the other is adjustable. The one sling is on the forward side of the main beam, and the aft sling toward the cab is maneuverable and had to be adjusted from the cab. Most current models out there are BFM (Beam Forward Machines), which means the beam is forward and the two sling adjusts are behind the beam. Both slings are adjustable. The new lift that we’re purchasing is a BFM. You have a lot of maneuverability with the slings, and the operator can adjust everything from the cab.

One of the newest moves for Marine Travelift is that they offer the ability to operate from the cab and also via remote control. You can operate alongside the machine, or wherever for that matter. It’s very beneficial, safer and more efficient. We bought our first remote control from Marine Travelift in 2004. It’s fairly standard today, but back in 2004 it was an option. That purchase is still in operation, it’s our 165-ton machine in Bellingham. There are a few manufacturers that don’t offer remote packages, but the more innovative ones do offer that package.

Q: Let’s get a sense of scale here. What are big and small sizes when we’re talking about industrial boat lifts?

In large part, if you looked at a cross section of the typical Pacific Northwest boatyard, the average boatyard comes in at around 55 tons like at our West Yard. There are tons that are 30- or 35-ton lifts as well. As you get higher in capacity, the number starts shrinking. It’s related to the cross section of the average boat size and it makes sense. At one point, I had three in that range, and currently I have two. We will probably hang onto our 55-ton machine at the Shilshole yard because it’s a capacity thing. We’re so busy we really need two machines. At the North Yard, we have two lifts, a 65- and 35-ton.

Q: So what’s the big deal about the new lift from Italy you’ve ordered? You seem pretty excited!

I’ve been actively looking for a new machine for at least two or three years now, and thinking about it for even longer. It’s my belief that anyone in business needs to look at their market and how to serve their market to the best of their ability, and look for new opportunities. We’ve seen an increase with regards to boat size in our customer base, and a lot of marinas have reconfigured a lot of their slips to accommodate larger vessels. We looked at our location in Seattle, and it’s a fairly small yard. We went through a recent expansion in 2016 because we were at capacity during peak season. So in conjunction with the size of the yard, I was looking for machines that would be more maneuverable. We added around 10,000 square feet, approximately 12 more boats stalls. Currently we can work with boats up to 60 feet, but we are working and expanding to serve boats up to 75 feet.

Seaview West

6701 Seaview Ave. NW,

Seattle, WA 98117

206-783-6550

Seaview Fairhaven

805 Harris Ave.,

Bellingham, WA 98225

360-594-4314

Seaview North

2652 Harbor Loop Dr.,

Bellingham, WA 98225

360-676-8282

It all comes down to maneuverability. I went out to bid, I looked at three different lift manufacturers and, ironically, one of them was in the States, Marine Travelift, and the other two were in Italy. I, of course, knew about Marine Travelift and have been a loyal customer, but I heard from folks to take look at Ascom in Italy. I took at hard look and went down to check some out in San Diego, and was about ready to make an order but came to know another one, Boat Lift in Italy. I got to tell you, it was cool to put my head up and look around a bit for once. Really do my due diligence and see what’s out there. Before I knew it, three weeks later, I found myself flown to Italy to check out the facility. I was blown away!

The largest size machine they had was a 400-ton, the smallest a 60-ton. Ours is an 80-ton.

Q: What are some specifics about Boat Lift machines that you like?

These guys have a huge manufacturing and fabrication company and are into building robotics. This machine is all-wheel drive, that means four-wheel steering, and the remote package is standard. The lift can turn 90 degrees virtually in place while crabbing. Amazing stuff! It can basically turn inside of itself. Talk about ultimate maneuverability.

There’s also no cab. When I saw that, I asked, ‘Where’s the cab?’ and the sales rep I was with replied, ‘Why do you need a cab?’ The cool thing is that it has three different ways of operation: remote, computer backup (a pendant hardwired to it like a computer mouse), and if all else fails, you can open a compartment to operate the machine manually.

On top of that, there’s two other items. We ordered what we call “extreme beam forward,” so the top beam, instead of being in line with the forward columns, is four feet forward. It gets that top beam away from the main beam so things like stays don’t have to be detached. Some will, but many won’t. The extreme beam forward also gets the obstacle away from flybridge and tophouse, so you can properly sling the boat and still have a balanced load.