Like many Seattle startups, from Microsoft to Amazon, Ballard-based Raptor Deck can trace its inception back to the most homegrown of headquarters: the garage.

Today, it’s the trusted purveyor of high-quality foam grip decking materials that provide additional comfort and traction on deck. Raptor Deck was first inspired by a simple solution sourced from goods that CEO Dan Kaseler found in his garage almost a dozen years ago.

Back then, Kaseler—well-known in the Northwest as an accomplished sailboat racer and sail designer, as well as for his innate knowledge of the wind-surfing and kite-boarding industries—was looking to add extra grip to his racing boat deck ahead of a world championship. He started experimenting with adhering foam similar to the non-skid versions he’d seen used on kiteboards and the rest, as they say, is history.

“I actually had the foam stashed in my garage with a plan to replace the awful blue carpeting on my boat’s trailer bunks.” he recalls with a laugh. “But after playing around, a light went off for me, and I ended up coating my whole cockpit floor.”

The homespun hack turned heads amongst his fellow competitors at the regatta, and soon Kaseler was fielding requests to outfit other racing vessels. As the side hustle became a business in the years that followed, power boaters and yachters also took notice. The incredibly stylish foam systems deliver extra grip, durability, and plush padding for maneuverability around the vessel and also help keep deck surfaces from getting scratched. He still fondly recalls one huge turning point along the way: the day he received a call from a boat builder in the Midwest asking him to come out and pattern all their new builds for Raptor Deck systems to be offered as an upgrade. “I went to Sea-Tac the next day, bought the only ticket I’ve ever purchased at the counter, hopped on a plane, and went out and patterned all their boats completely on the fly.”

Fast forward to 2021, and the brand has left the garage far behind. During the pandemic pause, Raptor Deck moved into the former West Marine space on Seaview Avenue, opening up a storefront space and expanding their manufacturing facilities. All of the decking kits are produced in-house and are custom made in a range of colors, thicknesses, and styles from templates matched to each boat’s specifications. DIY-driven customers can template their own boat and adhere the finished foam kit themselves, or Raptor Deck can handle the entire process from concept to creation to installation.

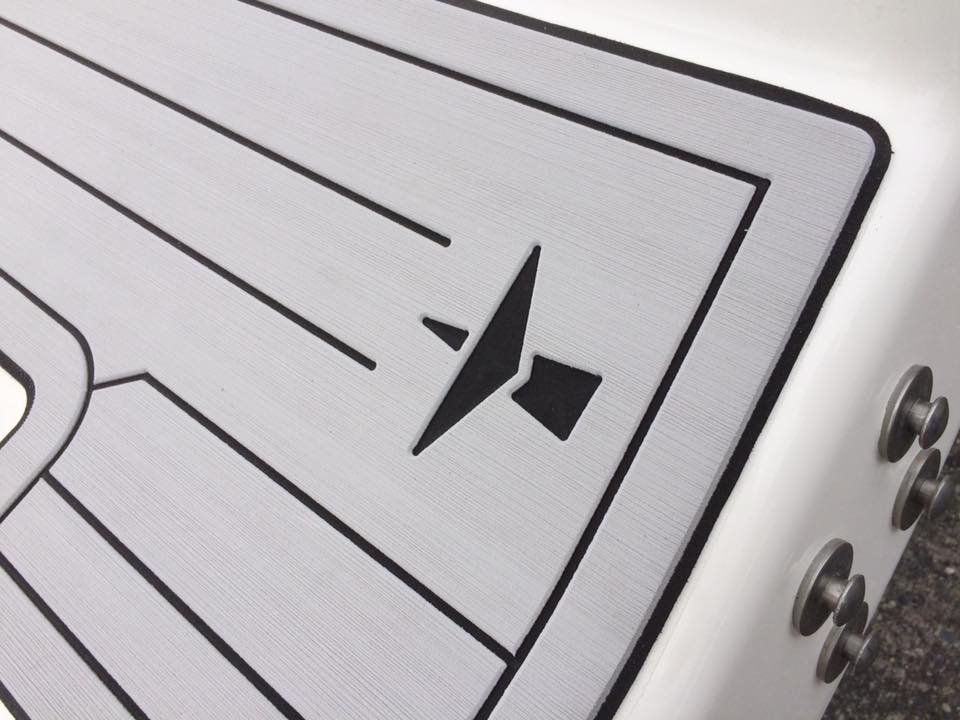

The most popular styles often resemble traditional wood planking, but because everything is drawn up, digitized, and made to order in Ballard, the team can also design more creative custom options and are always game to do so.

“We love a good napkin sketch,” Kaseler says. “We always say, just give us a seed of an idea and we can make something really cool with it.” Innovative applications have thus emerged, such as custom logos or graphics inlaid into the deck kit or on cooler tops. Then there are the exceedingly practical applications such as a recent Ranger Tug owner who noticed his water bottle was scratching the gel coat as it rattled around in the cup holder at the helm, so Kaseler and company cut a personalized bumper pad for him; issue solved.

“Everything is driven by the customer and we really maintain a constant openness to new ideas,” Kaseler explains. “And people are finding all kinds of interesting uses for it; turns out foam with glue is just extremely handy.”

Building on their banner year, Raptor Deck will soon debut the next evolution in marine non-skid tech. Kaseler believes the industry is shifting away from molded and painted textures to a future that utilizes options that are held in place with pressure-sensitive adhesives. Raptor will now also offer kits and parts cut from Harken Marine Grip, a more rubberized traction product. This new product is well suited to high-traffic areas and commercial-grade vessels like tugboats, fishing trawlers, ferries and the like.

“While Marine Grip doesn’t offer the same padded comfort, the material has exceptional durability, and truly unmatched non-skid properties for environments where safety is paramount,” he says.

In addition to dedicated kits, Raptor Deck will also offer mixed packages that utilize both materials. For recreational boaters, this could mean installing the softer foam for comfort on a main deck and benches, and then supplementing with the Harken Marine Grip in areas that need extra traction or endure excessive wear. Kaseler hopes to have initial styles available this month, with an expanded selection by spring 2022, so it looks like next year might just be another winning one for this hometown brand.

>> For more information on Raptor Deck and all their product lines, visit: raptordeck.com.